Why Some Signs Last for Years—and Others Don’t Make It to Closing Day

Not all signs are created equal, even when they look the same on day one. A real estate sign may appear sturdy when it’s first installed, but months later it can tell a very different story. Materials, ink chemistry, thickness, and environmental exposure all quietly determine whether a sign still looks professional—or whether it has already become a replacement problem.

The uncomfortable truth is that price alone doesn’t tell you how a sign will perform outdoors. Durability is a science problem, not a design problem. Understanding that difference can save time, money, and frustration, especially for signs that need to stay visible and credible throughout many listings.

This article breaks down what actually determines how long a sign lasts outside, why some signs age gracefully while others don’t, and how to choose the right option for real-world conditions.

Related reading: The Science Behind Real Estate Signs That Actually Sell Homes

The Myth of “All Signs Are the Same”

At a glance, many yard signs look identical. They’re the same size, use similar layouts, and install the same way. But what’s happening beneath the surface is where performance starts to separate.

A sign’s lifespan is shaped by the material it’s made from, the ink used to print it, how rigid the panel is, and what kind of weather it faces. When one of those elements is out of balance, signs tend to fail quietly—warping, fading, or cracking long before anyone expects them to.

If you’ve ever replaced a sign sooner than planned, you’ve already seen these forces at work.

↑ Back to top

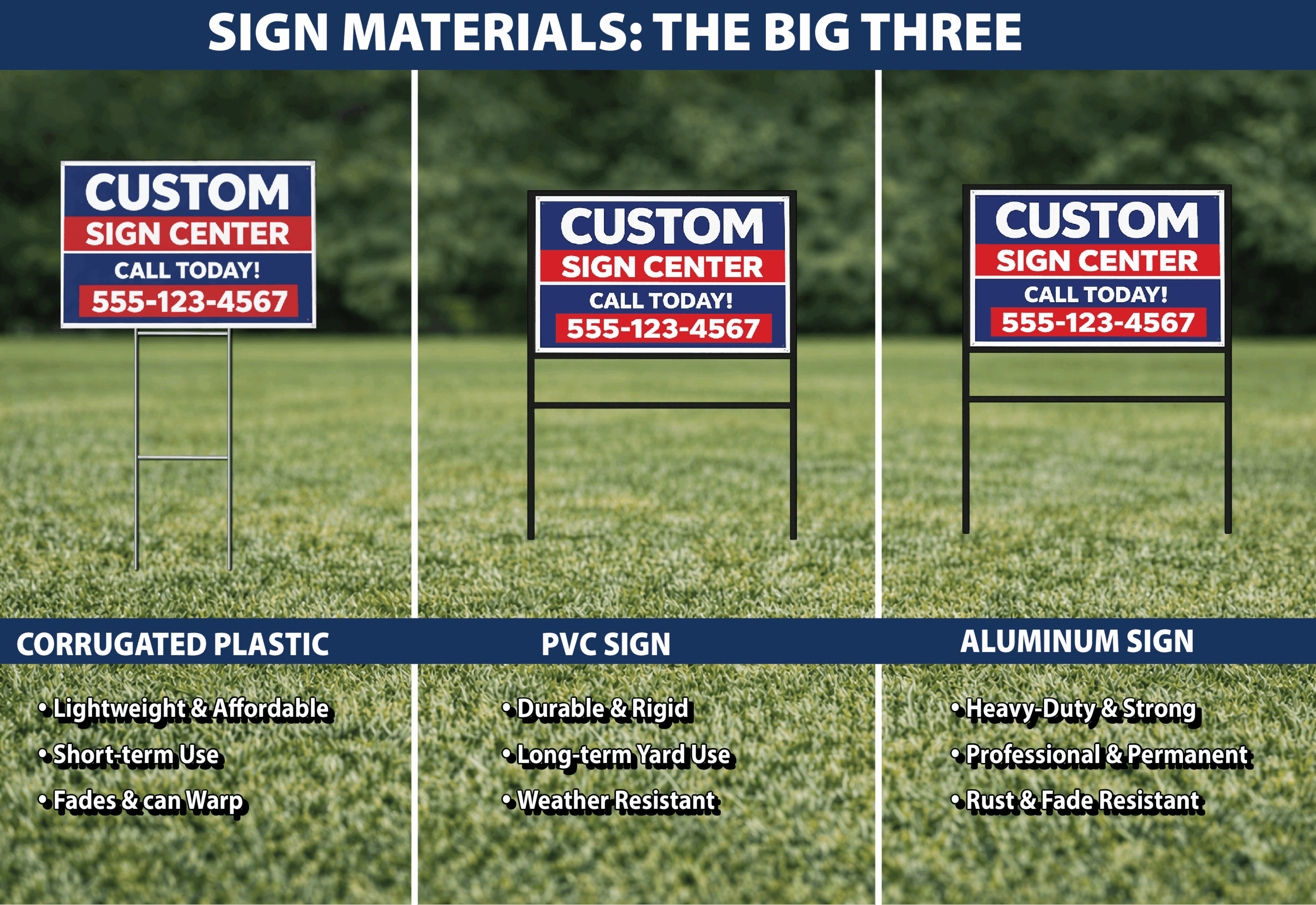

The Big Three Sign Materials and What They’re Really Built For

Most real estate signage falls into one of three material categories. Each has a purpose, and each performs best when it’s used for the right duration and environment.

Corrugated plastic, often called coroplast, is lightweight and affordable. It’s widely used for open houses, directional signage, and short-term listings where speed and cost matter. Because it’s flexible and easy to install, it excels in temporary situations. Over longer periods, however, repeated wind vibration and UV exposure can gradually cause warping or fading. That doesn’t make coroplast a poor choice—it simply means it’s designed for the right job, not every job.

and affordable. It’s widely used for open houses, directional signage, and short-term listings where speed and cost matter. Because it’s flexible and easy to install, it excels in temporary situations. Over longer periods, however, repeated wind vibration and UV exposure can gradually cause warping or fading. That doesn’t make coroplast a poor choice—it simply means it’s designed for the right job, not every job.

PVC signs step things up in terms of rigidity and durability. Expanded PVC panels are denser and stay flatter over time, which makes them a popular option for listings that need to look sharp for weeks or months. Thickness plays an important role here. Thicker PVC panels resist bending and stress far better than thinner alternatives, especially in windy conditions.

Aluminum and aluminum composite signs offer the highest level of durability. These materials are built for long-term exposure and are commonly used for commercial properties or installations where replacement is not something anyone wants to deal with. Aluminum isn’t overkill—it’s a form of risk management when brand perception, longevity, and visibility matter.

↑ Back to top

Ink Is Chemistry, Not Just Color

Low-quality inks can fade quickly outdoors, while UV-printed inks are engineered to maintain color, contrast, and readability over time.

Two signs can use the exact same artwork and still age very differently. The reason almost always comes down to ink chemistry.

Some ink systems are engineered to bond tightly to the surface and resist fading when exposed to sun, moisture, and abrasion. UV-cured inks are a prime example. They harden instantly during printing, creating a durable layer that holds color and contrast far longer outdoors.

Other inks may look fine at first but begin to lose clarity as exposure adds up. The difference may not be obvious in the first few weeks, but over time it becomes clear which prints were designed for outdoor performance and which were not.

The key takeaway is simple: the same design printed with different ink systems can have completely different lifespans.

↑ Back to top

Why Thickness and Rigidity Matter More Than You Think

Outdoor signs rarely fail all at once. Instead, they degrade gradually as wind, movement, and temperature changes apply constant stress.

Wind creates vibration, especially around fasteners and stakes. Panels that flex too much are more likely to bow, crack, or develop stress points. Thicker, more rigid materials reduce that movement, which directly reduces wear.

In plain terms, if a sign flexes excessively, it won’t last as long. Rigidity isn’t about overbuilding—it’s about minimizing fatigue over time.

Weather Is the Ultimate Stress Test

Prolonged exposure to moisture and weather can gradually break down sign materials that aren’t designed for long-term outdoor use.

Every outdoor sign faces the same forces. Sunlight breaks down pigments. Rain challenges ink adhesion. Cold temperatures increase brittleness and stress around attachment points. Seasonal swings accelerate all of it through expansion and contraction.

In regions with real seasonal variation, like the Midwest, signs experience these stresses repeatedly. A sign’s lifespan is determined not just by what it’s made of, but by what it’s expected to survive day after day.

↑ Back to top

The Hidden Cost of Cheap Signs

A sign that needs to be replaced multiple times often costs more than a sign purchased correctly from the start. The expense isn’t limited to materials—it includes time, reorders, production delays, and frustration.

There’s also a brand impact to consider. Warped panels, faded colors, and hard-to-read information send a message, whether intended or not. Durability reduces replacements, reduces phone calls, and reduces the likelihood of last-minute emergencies.

Related reading: The Science Behind Real Estate Signs That Actually Sell Homes

Choosing the Right Sign for the Real World

The best sign choice balances budget, exposure, and lifespan. Corrugated plastic works well for short-term and directional needs. PVC offers a strong middle ground for longer residential listings. Aluminum excels when longevity and stability are priorities.

The best sign choice balances budget, exposure, and lifespan. Corrugated plastic works well for short-term and directional needs. PVC offers a strong middle ground for longer residential listings. Aluminum excels when longevity and stability are priorities.

The right decision isn’t about buying the most expensive option—it’s about buying the right tool for the environment the sign will face.

Buy for the Environment, Not Just the Event

Signs don’t have to be disposable when they’re chosen thoughtfully. When materials and print methods are matched to real-world conditions, signs stay readable, professional, and effective for the duration they’re needed.

If you’re unsure which option fits your location or timeline, working with a sign provider who understands materials and exposure can help ensure your signage performs exactly as expected—outdoors, in real life, where it counts.

The difference between a sign that lasts and one that fails early is rarely accidental. It comes down to informed choices—materials selected for the environment, ink systems designed for outdoor exposure, and construction that anticipates real-world stress instead of ideal conditions. When those elements work together, signage stops being a recurring problem and starts being a dependable asset. The most effective signs aren’t just designed to look good on day one—they’re built to hold up, stay legible, and represent your brand well for as long as they’re in the field.

↑ Back to top

0 Comments